Modular Tubing Notcher System

1 847 623-7029

Tubing Notcher Benchtop Model

Tubing Notcher Benchtop Model with Linear Gauging Rail

|

|

This is the base model of the tubing notcher mounted onto a benchtop stand with a linear gauging rail attached.

Included:

Look down below for more information on the tubing notcher. |

Tubing Notcher on Rolling Base

|

This is the base model of the tubing notcher mounted onto a rolling base. The base also doubles as a storage cabinet for all of the accessories.

Included:

Look down below for more information on the tubing notcher. |

Tubing Notcher on Rolling Base with Linear Gauging Rail

|

This is the base model of the tubing notcher mounted onto a rolling base with a linear gauging rail attached. The base also doubles as a storage cabinet for all of the accessories.

Included:

Look down below for more information on the tubing notcher. |

Standard Deluxe Tubing Notcher

|

This is the base model of the tubing notcher mounted onto a rolling base. The base also doubles as a storage cabinet for all of the accessories. There is a linear gauging rail that comes with a set of fully indexable stops for increased cut repeatability.

Included:

Look down below for more information on the tubing notcher. |

CUSTOM ENGINEERING: We will custom engineer any part of this machine to fit your shop needs. Tell us your idea and we will give you a quote!

ALL IMAGES AND VIDEOS BELOW ARE OF THE STANDARD DELUXE TUBING NOTCHER

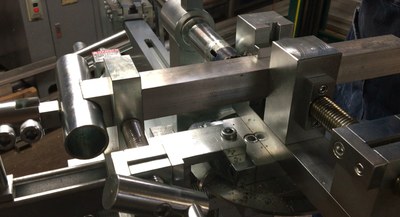

MORE VIDEOS THE MODULAR TUBING NOTCHER SYSTEM is designed to quickly notch or cope the ends of metal tubing, so two pieces of tubing can be welded together with clean, strong joints.

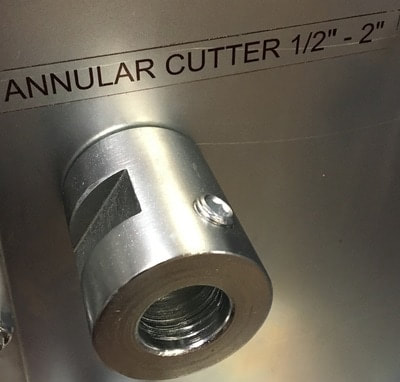

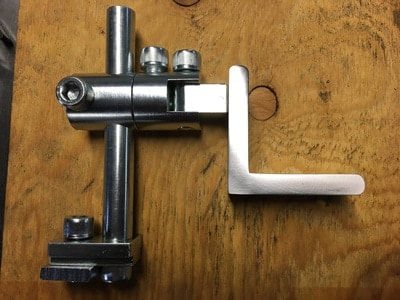

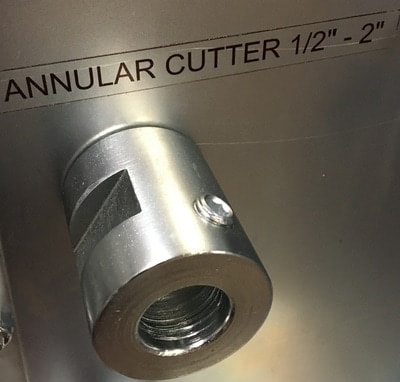

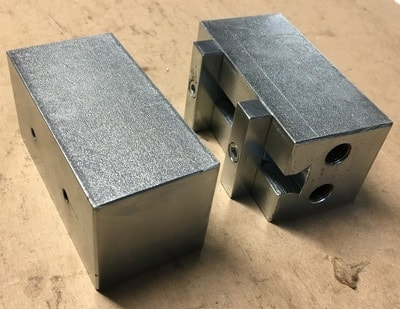

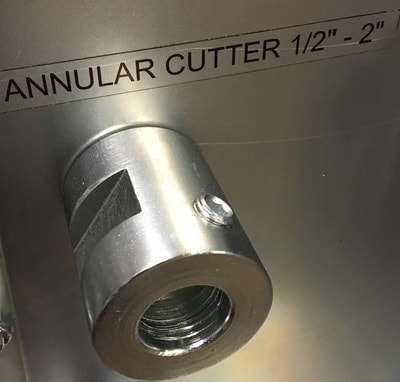

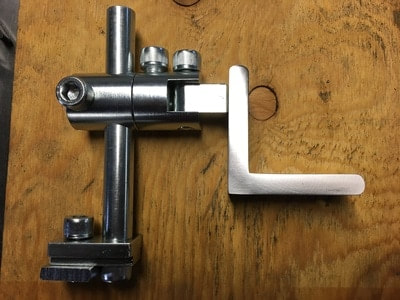

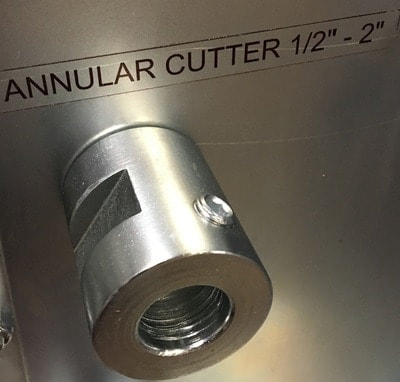

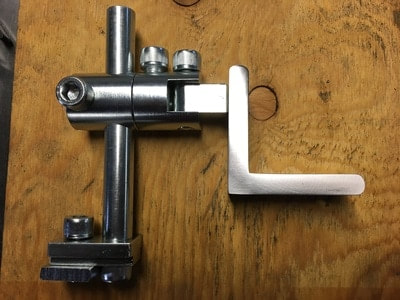

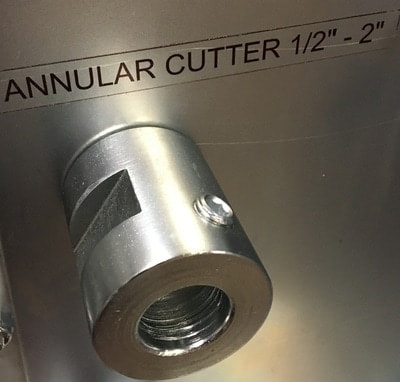

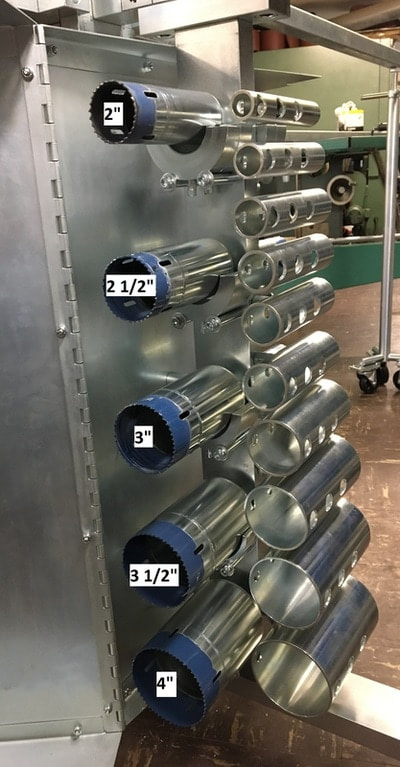

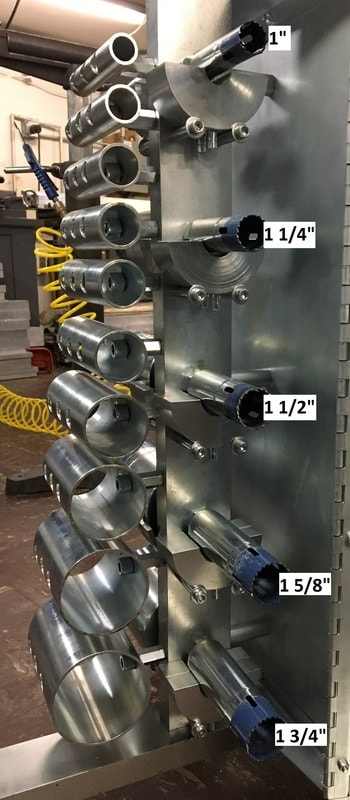

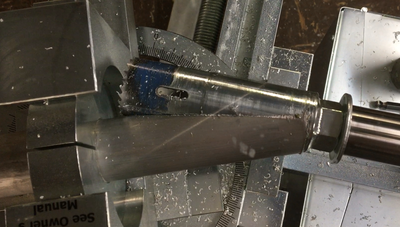

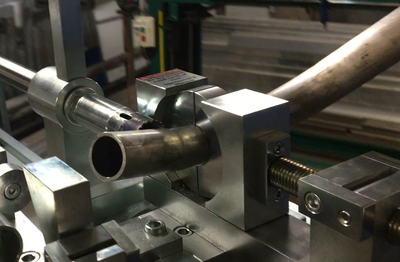

It is an ideal machine for production work with fencing, gates, roll cages, bicycle frames, stainless steel piping, or any other type of tubing work that requires joining multiple pieces together. CUSTOM ENGINEERING: We will custom engineer any part of this machine to fit your shop needs. Tell us your idea and we will give you a quote CLAMPING: Comes equipped with a main, and recommended additional support vise for tight, compact, rigid, and stationary clamping. TOOLING: The vise allows the tube to be set at any angle from 0 to 180 degrees. Using a variety of available for purchase extra deep cut hole saws, capable of extreme angles, notches can be formed in diameter of 1” 1-1/4” 1-1/2” 1-5/8” 1-3/4” 2” 2-1/2” 3” 3-1/2” 4” ADAPTERS FOR ADDITIONAL TOOLING: Also available are small and large hole saw adapters, annular cutter adapter, and a drill chuck adapter (with drill chuck) Above is an example of our extra deep cut hole saw coping an extreme angle. The set up for making this extreme angle took about 5 minutes. Clean fast and easy with the Modular Tubing Notcher System.

On the right is an example of the main vise holding a bent tube, ready to be coped in the radius. Our compact and tight vise design allows for rigid clamp pressure around the circumference of the tube. With plenty of available Y-travel, this tubing notcher can find the center of most if not all bent tube configurations.

|

Cope-To-Cope Procedure THOUGHT OUT MANUAL: Included with the machine is an owner's manual that is as thought out as the machine itself. This machine opens the door to setups not thought possible, so we have crafted step by step procedure lists with pictures detailing many different set ups and operations. We want you to have the knowledge to push this machine to the limit.

Examples of procedures covered in manual

|